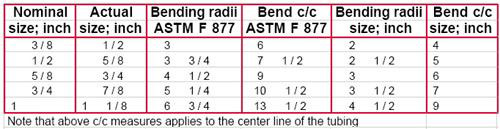

The information in this table is based on a minimum of 36" lengths:įor questions regarding bend radius for our other tubing products or for more sizes, contact our team or call toll-free in the US 1-80 or +1-80 internationally today to see how we can develop a precision solution to give you a competitive advantage or to request prototyping samples.įor expanded details for bend radius, tubing sizes, and resins, please see our catalog. For those tubings, bend radius does not apply.Īs a representative example, the table below is presented using our PTFE Industrial Wall tubing (0.030″ wall thickness, except where noted) to illustrate bend radius determination.

Note that not all of our tubing is flexible.

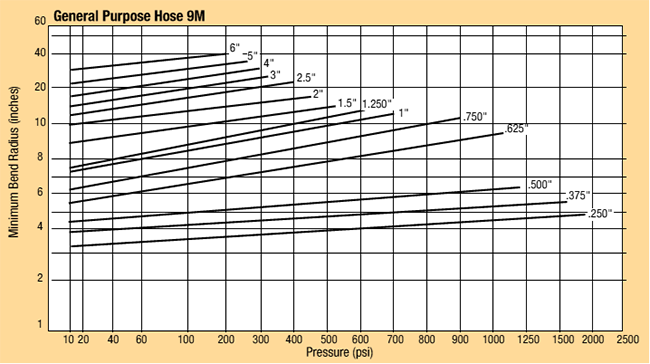

As a general guide, we have performed a series of bend tests that we hope will guide you in determining the size that is most suitable for you. Zeus prides itself in its sample program where we work with companies to find the right material and perfect size. The bend radius is established primarily by three different factors: outside diameter (OD) of the tubing, wall thickness, and resin that the tubing is made from. (2008) established an FE model for the numerical controlled (NC) bending of thin-walled. However, it did cause the values increase. springback radius with the bending angle of Ti-alloy tubes. Shape the Bend: Bending the pipe over a padded knee is the quickest way to bend copper pipe to an approximate 4- to 8-inch radius. This is a repository copy of An analytic model for tube bending springback considering different parameter variations of Ti-alloy tubes.

Or, if you do manage to get the right curve, ripples may develop on the inside of the curve. The question is often raised as to what the minimum bend radius is for a specific size of tubing. Bend Slowly: Bending the copper pipe quickly might still crimp it, even if it is properly supported.

0 kommentar(er)

0 kommentar(er)